high temperature fracture creep|metal deformity vs metal creep : factory The purpose of this paper is to review the high temperature creep and fracture behavior of the refractory metals, the high melting transition metals in Groups VA (V,Cb,Ta) and . WEBWe would like to show you a description here but the site won’t allow us.

{plog:ftitle_list}

Resultado da Ofertas incríveis!! Confira algumas das OFERTAS que preparamos para você. Compre pelo site ou WhatsApp (16)99625-0371 Entregamos na sua .

what is creep resistant to

frazier permeability tester

what is a creep deformation

High-temperature creep tests of additively manufactured (AM) and wrought nickel alloy 718 (IN718) were conducted at 650 °C and 704 °C at stresses ranging from 316 to 819 MPa.The purpose of this paper is to review the high temperature creep and fracture behavior of the refractory metals, the high melting transition metals in Groups VA (V,Cb,Ta) and . The high-temperature mechanical properties of the IFW joints were systematically analyzed. Under the creep testing condition of 680°C, the specimens exhibited creep fracture .

Outline. • Creep and high temperature failure • Creep testing • Factors affecting creep • Stress rupture life time behaviour • Creep mechanisms • Example • Materials for high creep . In this paper, the effects of the microstructure of as-welded Inconel 625 deposited metal on creep deformation and fracture behavior over broad temperature (600 °C–900 °C) .As high-entropy alloys (HEAs) are being actively explored for next-generation structural materials, gaining a comprehensive understanding of their creep, fatigue, and fracture behaviors is indispensable.

High temperatures in concrete can cause fracture or distributed cracking damage, as well as excessive or unstable deformation.Examines high temperature fracture, including nucleation of creep cavity, diffusional growth and constrained growth of creep cavities. A valuable reference to the main theories of high .

fx3300 permeability tester process

Creep-Enhanced Diffusive Cavity Growth and Elastic Accommodation. Hermann Riedel The room and high temperature (up to 600 °C) mechanical properties, with emphasis on the fracture toughness and fatigue resistance, of an α/β titanium alloy that was additively manufactured using the laser powder bed fusion (LPBF) technique were evaluated in the as-printed (α’ lath martensite with negligible β phase content) and heat-treated (α/β . The present research focuses on in situ monitoring of high-temperature creep damage in 2.25Cr1Mo0.25 V high-strength structural steel at 550 ℃ under various applied stress levels using the AE technique. To eliminate the noise signals that are unrelated to the development of creep damage, a denoising criterion based on the partial power of AE .These three aspects of mechanical properties are particularly important because (i) creep resistance dictates an alloy’s high-temperature applications; (ii) fatigue failure is the most frequently encountered failure mode in the service life of a .

Creep of crystalline materials at high temperatures is a thermally activated process and is governed by the mobility of point or line defects. . test (SRRT) to a commercially forged titanium-base alloy in evaluating: irreversible viscous strain, during primary creep at a constant temperature and quasi-constant microstructure, and its use to . During the high-temperature creep process, the formation of microvoids inside the material is a key factor for the material to fracture. . In this study, the creep behavior, precipitation evolution, and creep fracture of a 17Cr ferritic heat-resistant stainless steel were investigated at stresses of 15–90 MPa and temperatures of 973–1123 . Creep damage and fracture at high temperature 287 Temperature PC) 750 700 650 600 550 0 1.0 1.1 1.2 I/T x 103 (1) Fig. 3. CCG rate vs temperature [17]. Figure 2 shows the relationship between and A] at different temperatures and Fig. 3 shows the effect of temperature on the CCG rate for different K. In the constant temperature case, from eq .

It then concentrates on creep rupture by cavity. | Find, read and cite all the research you need on ResearchGate . Book PDF Available. Fracture at High Temperatures (MRE) January 1987; DOI:10. .

The demands on materials at high temperatures are steadily increasing for economical and ecological reasons. . Attention will also be paid to thermomechanical treatment and hot shaping as well as testing high temperature creep, fatigue, and fracture behavior on standard or sub-sized specimens composed from heat-resistant steels and alloys .

During high-temperature creep, Re is easily expelled from the γ′ phase under high temperatures and applied loads, increasing the diffusion ability of other elements and resulting in KW being activated again to slip on the {111} plane, which is the main reason why the alloy containing only Re retains less of a KW lock under high-temperature .

After high-temperature creep, the fracture surface of rock sugar-like grains with different depths and shades are shown in Fig. 7 f. The morphology of the fracture surface is similar to that of its grains, while there are intergranular cracks and a large number of grain boundary stripped phases in Fig. 7 .

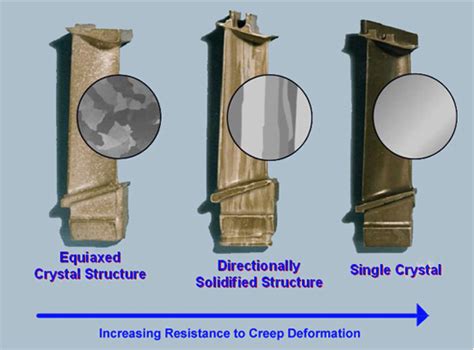

The high-temperature creep deformation and fracture behavior of a directionally solidified Ni-base superalloy DZ951 have been investigated over a wide stress range of 110 to 880 MPa at high temperatures (700 °C to 1000 °C). In this article, the detailed creep deformation and fracture mechanism have been studied. The results show that the creep curves exhibit . In this study, the creep deformation behavior of conditioning-treated Co-Cr-W-Ni-based cast superalloy with and without B and Zr additions was investigated using constant load creep tests conducted at temperatures of 700 °C (973 K) and 800 °C (1073 K) and stresses ranging from 200 to 400 MPa. For both alloys, secondary creep strains were analyzed in .High-temperature creep of metals is characterized by the fact that in the body, along with the accumulation of irreversible creep deformations, the formation and development of defects (pores, micro- and macrocracks) occurs, leading to fracture. In 1826, the phenomenon of creep was observed by Claude Louis Marie Henri Navier. It is known that the stress exponent under low temperature power law creep condition is higher for high temperature case: for dislocation creep, low temperature power creep has n value of 5–7 while high temperature power creep has 3–5 [61]. Fig. 6 (c) shows the stress exponent for H-5 alloy together with the reported values from Refs.

High temperature creep fracture behavior of nickel-base single crystal superalloys Xiangfeng Liang 1, Jili Wu , Xizhou Kai , and Yutao Zhao1 1Jiangsu University School of Materials Science and Engineering September 13, 2023 Abstract This study investigated the creep performance, fracture characteristics, and creep mechanisms of the nickel-base single crystal

Download Citation | High Temperature Heat-Treated Effect on Creep Fracture | The creep failure behavior of brittle rocks subsequent to high-temperature heat treatment holds significant . This study investigated the creep performance, fracture characteristics, and creep mechanisms of the nickel-base single crystal superalloy DD406 under conditions of 1100°C and 140MPa. Results of creep tests of two Fe-27 at. % Al-based alloys with additions of 2.7 and 4.8 at. % of niobium conducted in the temperature range from 650 °C to 900 °C in the authors’ laboratory are .

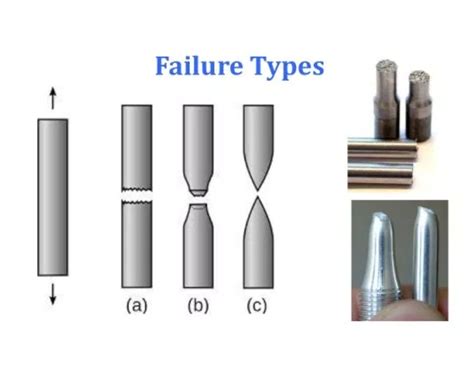

The dominant mechanisms of creep fracture at both low temperatures (below 1500 °C) and high temperatures (above 1500 °C) were examined. In the low-temperature region, creep fracture is dominated by the diffusional creep with less than 1% total strain contribution from grain boundary cavitation. Creep testing reveals how high-temperature materials deform over time under constant stress, critical for designing durable components. . Creep deformation, microstructural evolution, and final fracture in such materials are, therefore, significantly influenced by other phenomena like creep-buckling and creep fatigue.

With continued high-temperature operation, creep cracks grow from the cusp and ultimately weaken the cross section to the point where failure occurs. Creep failures are characterized by: bulging or blisters in the tube ; thick-edged fractures often with very little obvious ductility ; longitudinal "stress cracks" in either or both ID and OD .

At high stresses and temperatures, the creep fracture was dominated by plastic straining of the matrix and graphite nodules. At lower stresses and temperatures, it was caused by cavity nucleation and diffusive growth, leading to microcracks and voids without any signs of deformation in the matrix.

Creep is a very important phenomenon if we are using materials at high temperature. Creep is very important in power industry and it is of the highest importance in designing of jet engines. . Creep becomes a problem when the stress intensity is approaching the fracture failure strength. If the creep rate increases rapidly, the strain becomes .

The dominant mechanisms of creep fracture at both low temperatures (below 1500 °C) and high temperatures (above 1500 °C) were examined. In the low-temperature region, creep fracture is dominated by the diffusional creep with less than 1% total strain contribution from grain boundary cavitation. Creep usually occurs at high temperatures but can also occur at room temperature. Good examples are lead or glass. . In the final stage of creep, called tertiary creep, the creep rate increases rapidly until fracture occurs. Figure 1: Typical creep curve showing the three stages of creep in a constant load test [2].Combining normalized creep curve with the performance degradation law of unidirectional laminates, the high-temperature creep fracture time equation for unidirectional laminates can be determined. The specific method is as follows: Firstly, at different temperatures, the creep stress level of creep fracture data is normalized by the ultimate .

Materials Science and Engineering, A176 (1994) 71-78 71 High temperature fracture Horst Vehoff MPI fiir Eisenforschung, Max Planck Strafle 1, W-4000 Diisseldorf 1 (Germany) Abstract Deformation and fracture of materials at elevated temperatures are time-dependent processes.

Aposte contra outros jogadores. Cassino Online, jogos de cassino online que ganha dinheiro real.MINES, CRASH, the best game

high temperature fracture creep|metal deformity vs metal creep